How was the Aluminum expanded metal produced? Let鈥檚 see the detailed production process together.

1.Raw material preparation.

We only buy material from big factories, and because we have big demand of the material every month, the raw material factory always share us the most competitive price and quick lead time, so that we can offer better price and fast delivery time for our customers.

2.Stretching of the metal.

Our workers will measure each pieces while producing, once they find that there is a mistake, they will adjust the machine right away.

3.Leveling the mesh

After stretching, the mesh is not always 100% flat, so we need the leveling machine to make it flat. Different sizes of mesh requires different sizes of leveling machine, the diameter and quantity of the rolls are different, The widest leveling machine we have is 3.3 meters.

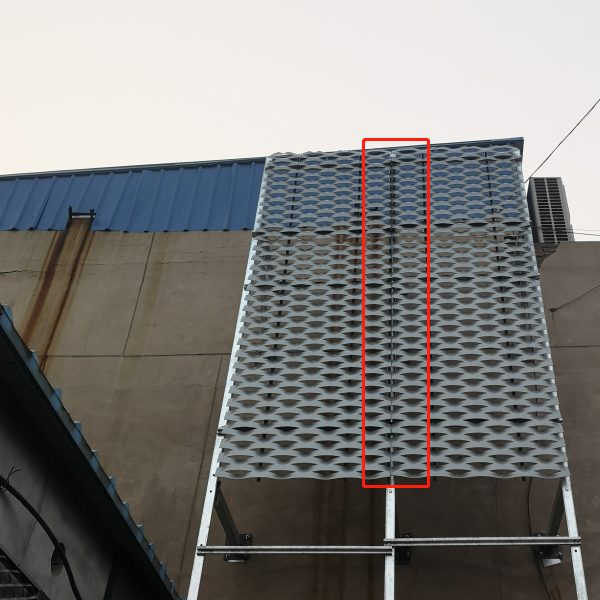

4.Cutting of the four side of the mesh

The customer required that the edges of the mesh must be combined as one unique one after installation on the wall. So we have to cut each side of the mesh to ensure different pieces will in good match.

Hole matches well when see it from a distance. (this is our test for installation in our own factory)

5.Welding the frame at the back side.

6.PVDF painting of the mesh.

6.1 Cleaning the mesh

There are 3 process of the cleaning, first acid cleaning, the most important step for good powder coating, it will help to remove all the Impurities and oil during the production and transporting. then we will use the pure water to clean it twice. Third, dry it by big dryers.

Cleaning before the coating is the key point to make the surface smooth, and improve the Adhesion, as well as extend the service life of the mesh.

And cleaning is right the difference between us and other factories, we are the only factory who will do the cleaning carefully in our area.

6.2 PVDF Painting or Powder Coated

All our painting workers are skilled worker with years experience, the powder coating layer will be smooth and share same thickness.

6.3 Baking

After painting the mesh need high temperature baking, PVDF Painting required 230鈩 temperature and powder coating required 180鈩冦€侟/p>

Test of the film thickness.

The international standard film thickness for PVDF Painting is over 35 渭m, and for powder coating is over 60渭m.

7.Package of the mesh.

General package will be plastic bubble inside, and wooden box outside. And sometimes customer will require simple pallet package, to save space and easier transportation.

Post time: Jan-15-2023