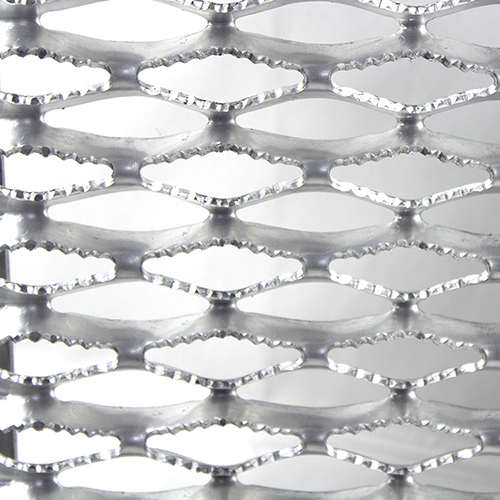

Perforated Metal Sheet, also known as perforated sheet, perforated plate, or perforated screen, belongs to a type of sheet metal that has been manually or mechanically stamped or punched to produce a pattern of holes, slots, or decorative shapes.

Materials utilized to manufacture perforated metal sheets comprise fluorocarbon, stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, Monel, titanium, plastic, and more. Here let’s talk about the Perforated Sheet made from Fluorocarbon.

Do you have a familiar feeling when hearing about the name? It’s because fluorocarbon covers an extensive family of compounds, including organics comprised of fluorine, chlorine and carbon, along with synthetics made from hydrocarbons, which has been used in everything from Teflon to Freon.

So what about the produing peocess of the perforated metal sheet? The procedure of fluorocarbon perforated metal sheets has been practiced for over 150 years. In the late 19th century, metal sheets were fabricated as an efficient approach of separating coal.

Modern perforation sheeting methods refer to the usage of technology and machines. General equipments adopted for the perforation of metal consist of rotary pinned perforation rollers, die and punch presses, and laser perforations.

We can see the obvious development of the fluorocarbon perforated metal sheet, which show the increasing improvement of the industrial refinement.

Post time: Jan-15-2023