We’re specialized in manufacturing expanded metal, aluminum expanded metal, perforated metal, safety grating and laser cut panel. Aluminum material are suitable for our all products and it’s a good choice. Aluminum 1 series, 2 series and 3 series are most widely used in industry. Today let me talk about the differences of aluminum 1 series, 3series and 5 series.

(1) Aluminum 1 series: 1060 1070 1100 etc.

Features:

-

More than 99.00% aluminum

-

Good electrical conductivity

-

Good corrosion resistance

-

Good welding performance

-

Low strength

-

Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap.

Application range:

High-purity aluminum (aluminum content above 99.9%) is mainly used in scientific experiments, chemical industry and special purposes.

(2)Aluminum 2 series: 2011 2014 2017 etc.

Features:

-

Aluminum alloy with copper as the main alloy element.(copper content is between 3 and 5%).

-

For 2011 alloy, we should pay attention to safety protection (2011 alloy will produce harmful gases in the smelting process) .

-

2014 alloy is suitable for aerospace industry and has high strength.

-

The strength of 2017 alloy is slightly weaker than the 2014 alloy, but is easier to process with.

-

2014 can be strengthend by heat treatment.

Application range:

Aviation industry (2014 alloy), screws (2011 alloy) and industries with high temperature (2017 alloy).

(3) Aluminum 3 series: 3003 3004 3005 etc.

Features:

-

Aluminum alloy with manganese as the main alloying element (1.0-1.5% of manganese).

-

It can not be strengthened by heat treatment

-

Good corrosion resistance

-

Good welding performance

-

Good plasticity (close to super aluminum alloy).

Application range:

seamless oil pipe (3003 alloy) used on aircraft and cans (3004 alloy)

For aluminum material, the bigger the series, the harder it is and the more expensive it is. Do you understand their differences ?

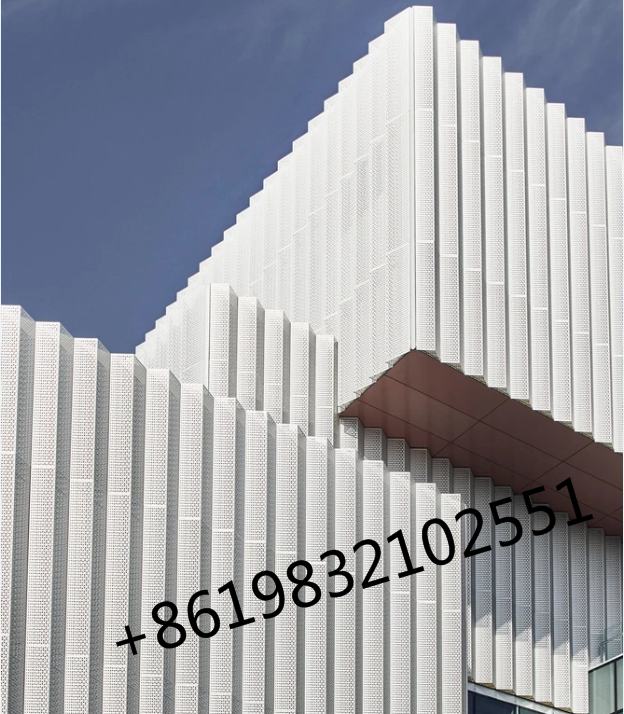

I attached several product photos with aluminum material for your reference.

|

|

|

|

If you need expanded metal, aluminum expanded metal, perforated metal, safety grating and laser cut panel or any other question, please don’t hesitate to contact me.

Whatsapp: +86 19832102551

Email: helen@huijinwiremesh.com

Wechat: 19832102551

Post time: Jan-15-2023